What are the properties of aluminum composite panels

What are the properties of aluminum composite panels

Super peeling degree

The aluminum-plastic composite panel adopts a new process, which improves the most critical technical index of the aluminum-plastic composite panel-peel strength to an excellent state, so that the flatness and weather resistance of the aluminum-plastic composite panel are improved accordingly.

Material is easy to process

The weight per square meter of aluminum composite panel is only about 3.5-5.5 kg, so it can reduce the damage caused by earthquake disaster, and it is easy to handle. Various shapes such as planing, bending into arcs and right angles can cooperate with designers to make various changes, and the installation is simple and fast, which reduces the construction cost.

Excellent fire performance

The middle of the aluminum composite panel is a flame retardant material PE plastic core material, and the two sides are extremely difficult to burn aluminum layers. Therefore, it is a safe fireproof material that meets the fire resistance requirements of building regulations.

impact resistance

It has strong impact resistance, high toughness, no damage to the topcoat by bending, strong impact resistance, and no damage caused by wind and sand in areas with large sandstorms.

Super weather resistance

Due to the use of KYNAR-500-based PVDF fluorocarbon paint, it has unique advantages in weather resistance, no matter in the hot sun or in the cold wind and snow, it will not damage the beautiful appearance, up to 20 years. fade.

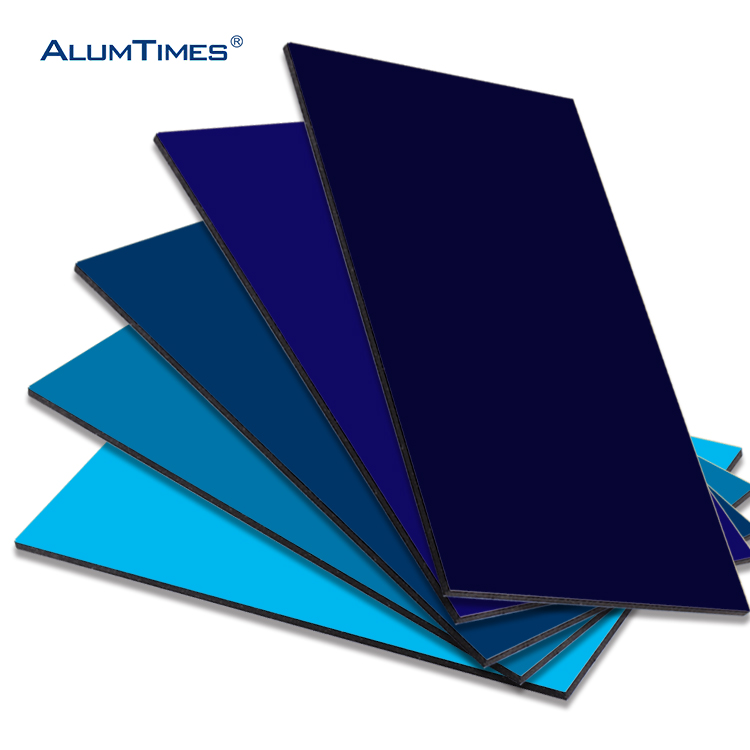

Uniform and colorful coating

After chemical treatment and the application of Henkel's film technology, the adhesion between the paint and the aluminum-plastic panel is uniform, and the colors are various, allowing you to choose more space and show your individuality.

Easy to maintain

Aluminum-plastic panels have been significantly improved in terms of pollution resistance. my country's urban pollution is relatively serious, and it needs maintenance and cleaning after a few years of use. Due to its good self-cleaning properties, it only needs to use a neutral cleaning agent and water, and after cleaning, the board will be permanently as new.

easy to process

Aluminum-plastic plate is a good material that is easy to process and form. It is also an excellent product for the pursuit of efficiency and time, which can shorten the construction period and reduce costs. Aluminum-plastic panels can be cut, cut, slotted, band sawed, drilled, countersunk, or cold-formed, cold-folded, cold-rolled, riveted, screwed, or glued.

Search

Categories

- Aluminum Panel

- _ Aluminum CNC Carved Panel

- _ Aluminium Decorative Panel

- _ Aluminum Column Cover

- _ Aluminum Meshed Panel

- _ Aluminum Perforated Panel

- Aluminum Metal Ceiling

- _ Artistic ceiling

- _ Clip in ceiling

- _ Lay in ceiling

- _ Grid ceiling

- _ Strip ceiling

- _ Round pipe ceiling

- Aluminum Composite Panel

- _ PE/PVDF ACP

- _ Wooden/Stone ACP

- _ Brush/Mirror ACP

- _ Pearl Sparkle/Glossy ACP

- _ Signboard ACP/Advertising ACP

- Stainless Steel

- _ Stainless Steel Rod

- _ Stainless Steel Fence

- _ Stainless Steel Handrail

- _ Stainless Steel Pipe

- _ Stainless Steel Panel & Coil

Send Email

Send Email 13928849689

13928849689