Aluminium Composite Panel Details

| Aluminium Composite Panel Details |

1)Material:

A) Front : aluminium alloy sheet coated fluoro-carbon resin (PVDF) with Nano lacquer.

B) Core: nontox low density polyethylene.

C) Back: aluminium alloy sheet coated with polyester resin painting.

D) Surface coating thickness: 32μ±1μ.

E) Aluminium alloy: 3003 H24.

F) Sheet thickness: 0.3mm,0.4mm,0.5mm .

2)Dimensions:

A) Thickness: 3mm,4mm,6mm,8mm,10mm.

B) Width: 1220mm,1250mm,1500mm,1570mm,1800mm,2000mm(max).

C) Length: 2440mm,3050mm,3200mm( max:6000mm).

D) Weight: 5.5kg/sqm baesd on 0.5/4mm thickness.

E) Standard size:1220*2440mm.

F) Qty/20'fcl:4mm/2380sqm; 3mm/2977sqm.

G) Non-stanard size are available according to requirement.

3)Standard:

A) West Europe standard ( Germany DIN Standard).

B) The EAST Europe standard ( Russian standard ).

C) The commonweathlth standard (U.K BS Standard ).

D) The North America ASTM standard.

4)Alumtimes® ACP compared with different products( Lightness / Rigidity ):

The composite structure of Alumtimes® results in an impressive strength-to-weight ratio, even when comparing large panel sizes. Despite its low weight, which makes Alumtimes® easy to transport and handle in the factory and on site, its rigidity and high strength make the panels keep their shape and remain flat, even when exposed to extreme temperature changes. Comparison of thickness and weight of panels with equal rigidity.

5) Alumtimes® ACP compared with solid aluminium:

Required thickness and actual weights of panels with same rigidity

Alumtimes® ACP | Aluminium | ||||

Rigidity (E J) | Section modulus | Thickness | Weight | Thickness | Weight |

1250 kN cm2/m | 1.25 cm3/m | 3 mm | 4.5kg/m2 | 2.7 mm | 7.3kg/m2 |

2400 kN cm2/m | 1.75 cm3/m | 4 mm | 5.5kg/m2 | 3.3 mm | 8.9kg/m2 |

6) Alumtimes® ACP Physical Properties for Panel:

Panel density | 5.5kg/m2 |

Peel Strength | Average 7.0 N/mm |

Tensile Strength | 52.5 Mpa |

Flexural Strength | 100.0 Mpa |

Shear Strength | 28.1 Mpa |

Search

Categories

- Aluminum Panel

- _ Aluminum CNC Carved Panel

- _ Aluminium Decorative Panel

- _ Aluminum Column Cover

- _ Aluminum Meshed Panel

- _ Aluminum Perforated Panel

- Aluminum Metal Ceiling

- _ Artistic ceiling

- _ Clip in ceiling

- _ Lay in ceiling

- _ Grid ceiling

- _ Strip ceiling

- _ Round pipe ceiling

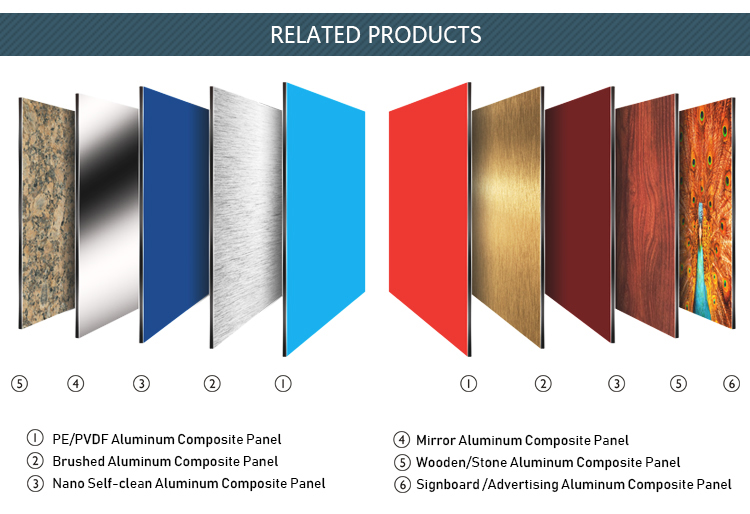

- Aluminum Composite Panel

- _ PE/PVDF ACP

- _ Wooden/Stone ACP

- _ Brush/Mirror ACP

- _ Pearl Sparkle/Glossy ACP

- _ Signboard ACP/Advertising ACP

- Stainless Steel

- _ Stainless Steel Rod

- _ Stainless Steel Fence

- _ Stainless Steel Handrail

- _ Stainless Steel Pipe

- _ Stainless Steel Panel & Coil

Send Email

Send Email 13928849689

13928849689